Unbrako exhibited at Delhi Fastener Fair from 19 to 20 May 2016. A big thank you to everyone for an overwhelming response to our wide range of Unbrako Stainless Steel Fasteners. With advanced manufacturing, engineering & logistics facilities, and AD 2000 certification, Unbrako is equipped to provide technical support and full-service package. Unbrako’s focus is on building long term relationships with its customers.

Widest Range of Fasteners

Quote or Enquiry

Advantages built into every detail

Latest News

Successful show at Delhi Fastener Fair

We are Moving!

To accommodate for our unprecedented growth in the US market, our current space in the Los Angeles warehouse was not enough. We have moved to a much bigger warehouse in Downey, almost 4 times the size. This will allow us to supply directly to all projects, distributors & customers our entire product range at very competitive prices. Come say hello at 11939 Woodruff Ave, Downey, CA 90241 – USA

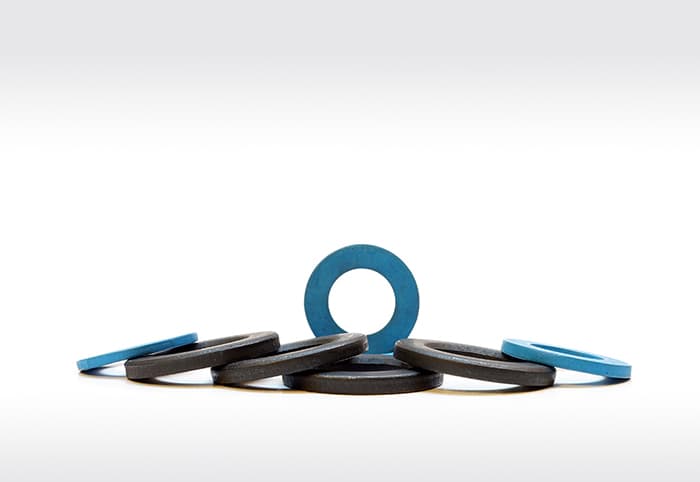

Unbrako Precision now in Stainless Steel

Unbrako fasteners known for quality, safety and innovation for over 100 years, are now available in 304 and 316 stainless steel – AD 2000 Merkblatt WO Certified. These high-tensile fasteners offer excellent corrosion resistance.

A complete range of Unbrako stainless steel fasteners including socket head screws, hex head screws and nuts, washers (plain & spring), threaded rod and socket set screws is now available in A2-70, A2-80, A4-70, A4-80, A4-90 and A4-100.